Lotions pumps

Over 17 years of experience, NingBo Synkemi Imp. & Exp. Co Ltd. Which is specialized in the foreign trade business. Our company provide a variety of general merchandises with excellent quality, unique design, low price ,swift delivery, prompt response and cost efficiency .

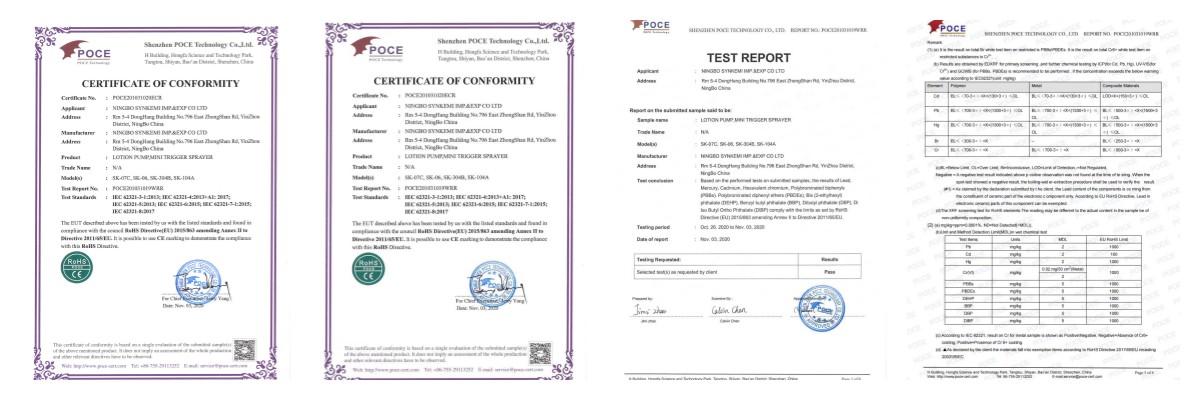

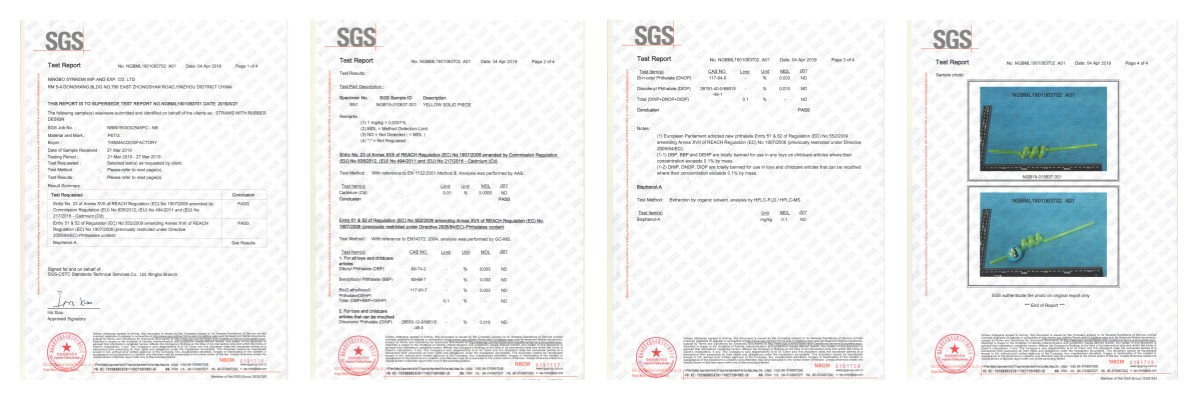

All of our products have the required certifications all over the world, we can provide basic CE certifications and other certifications of Plastic Lotion Dispenser Pump as you require.

OEM pp lotion pump dispenser has been used in the hair care, personal care, pet care, automotive and home care industries.

A variety of left/right lotion pump styles are in-stock and made of the highest quality PP plastics to ensure reliable long-term usage.

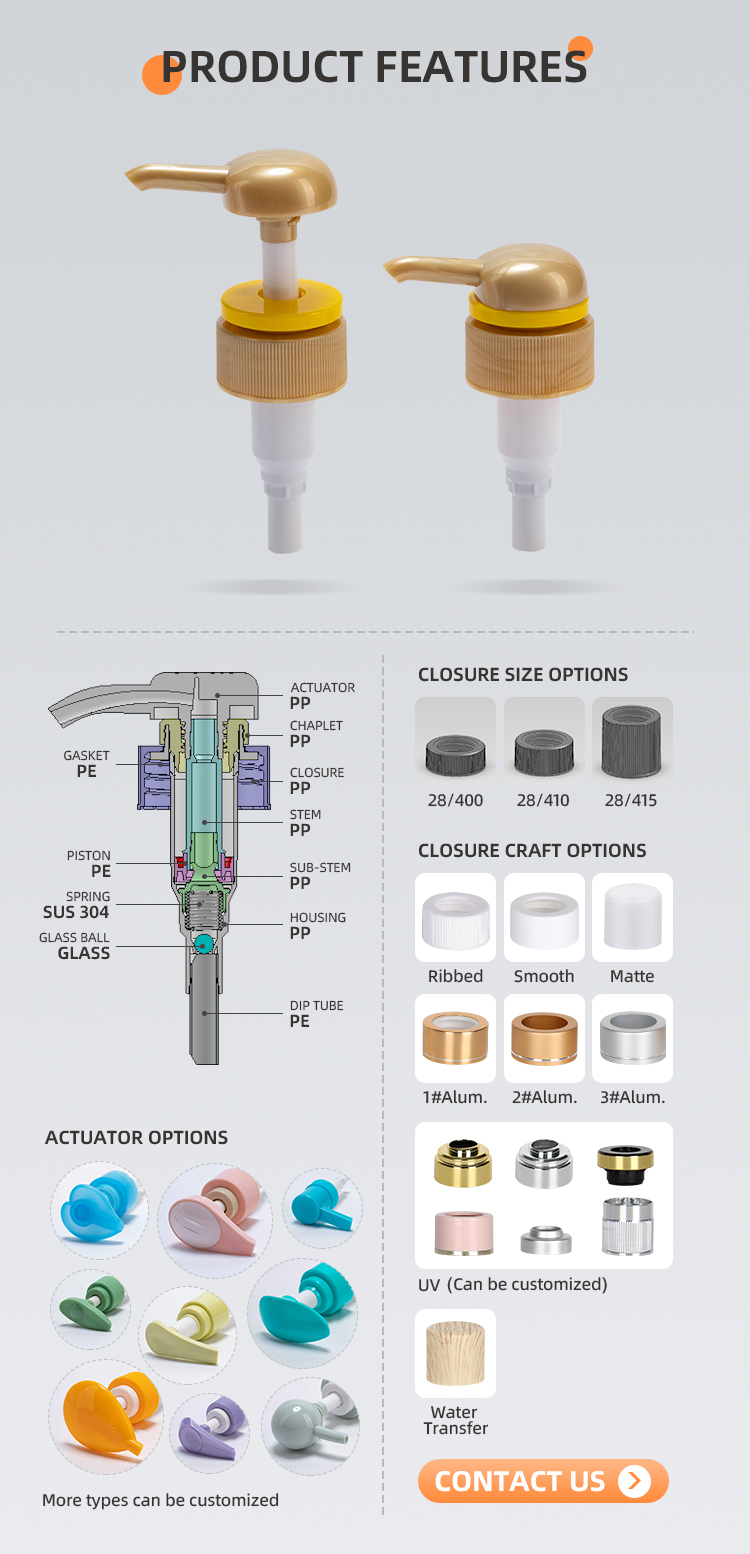

A conventional cosmetic lotion pump is often composed of a nozzle/head, an upper pump column, a lock cap, a bottle cap, a pump plug, a lower pump column, a spring, a pump body, a straw and other accessories. According to the structural design requirements of different pumps, the related accessories will be different.

Most of the accessories of the plastic lotion pump cap are mainly made of plastic materials such as PE, PP, and LDPE, and are molded by injection molding. The main components of the pump head can be applied to electroplating, anodized aluminum cover, spraying, injection molding and other methods.

Both the surface of the pump head and the surface of the braces can be printed with graphics and text, and can be processed by printing processes such as bronzing/silver printing, silk screen printing, and pad printing.

According to the lock head: According to the lock head: up and down lock, left and right lock, buckle lock, no lock.

According to the structure: spring external pump, anti-water emulsion pump, high viscosity material pump

According to the pumping method: vacuum bottle and straw type

According to the pump output: 0.15/ 0.2cc, 0.5/ 0.7cc, 1.0/2.0cc, 3.5cc, 5.0cc, 10cc and above.

According to the material : aluminum lotion pump and plastic lotion pump dispenser

Market Distribution

Why choose Synkemi

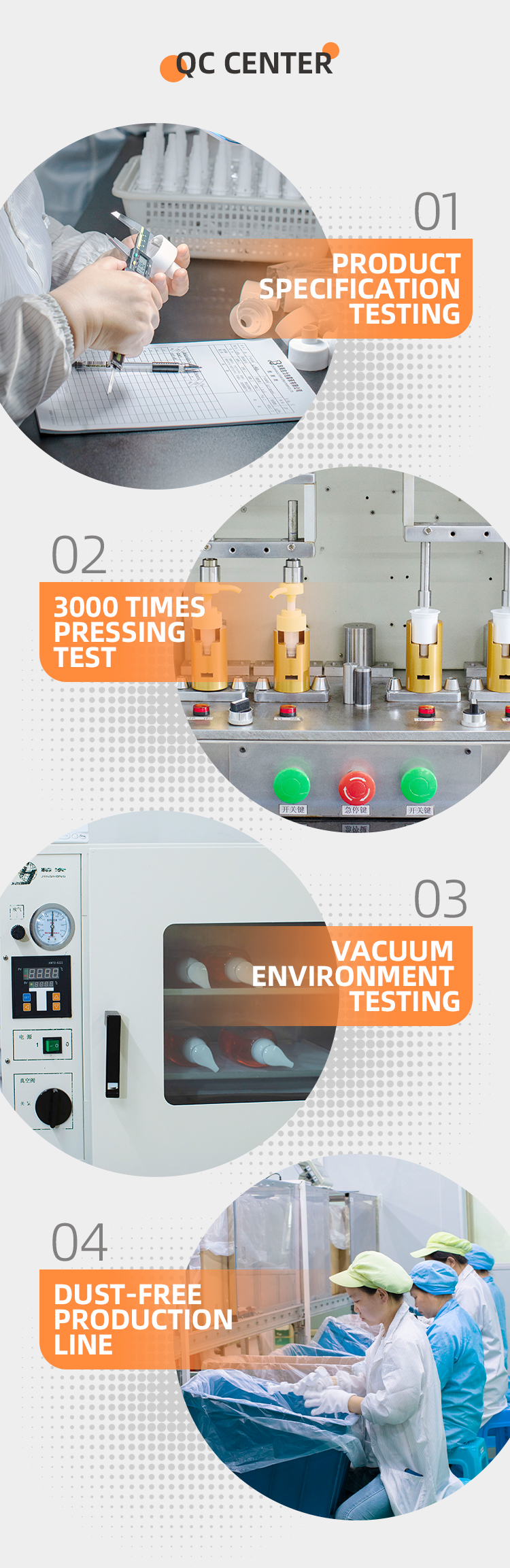

how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

what can you buy from us?

Nail Polish Remover Pump, foam trigger sprayer, metal Soap Dispenser Pump,Lotion Pump,Treatment Pump,Foam Pump,Mist Sprayer,Lipstick Tube,Nail Pump,Perfume Atomizer,Lotion bottle,Plastic Bottle,Travel Bottle Set,Bath Salt Bottle,Plastic cosmetic tube,Cream Jar..

why should you buy from us not from other suppliers?

Your inquiry related to our products or prices will be replied in 24hrs.

We have well-trained and experienced staffs to co-operation with you.

Protection of your sales area, ideas of design and all your private information.

What's the delivery time?

Generally 15-30 days,according to your quantities.

How can I get some samples?

We are honored to offer you samples.

We sincerely invite you to talk with us and look forward to the opportunity of working with you.

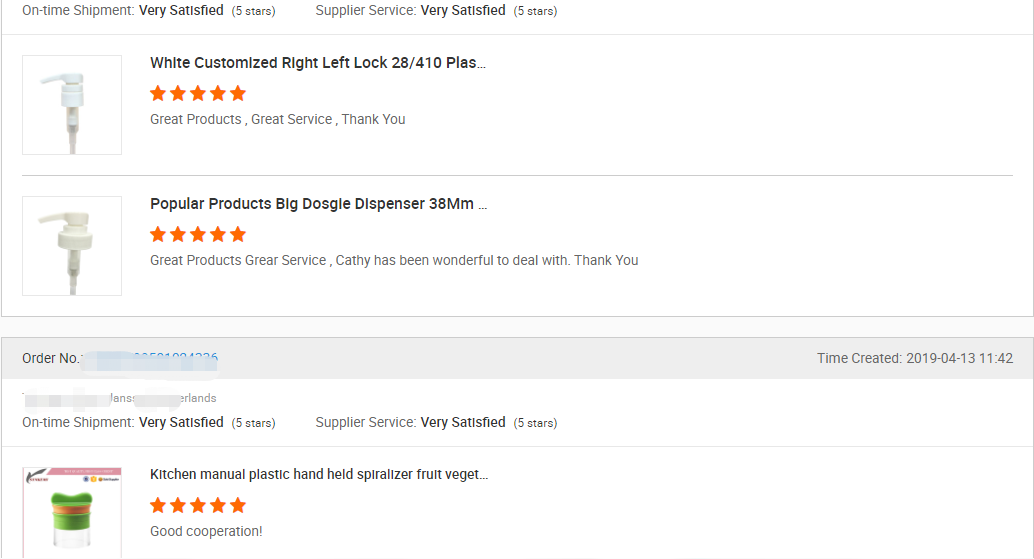

Some customer comments

How To Use Lotion Pump Correctly

Cosmetic lotion pump heads are found in most cosmetic packaging, which can facilitate people to take cosmetics. But sometimes the pump head will be damaged if it is not used correctly. So, how to use the cosmetic lotion pump head ?

1. When using cosmetics, press the pump head gently. If you use too much force, it will cause too much cosmetics to be sprayed out at one time, which will cause waste of cosmetics and damage the pump head.

2. Pay attention to tighten the bottle cap when using the cosmetic lotion pump head. If the bottle cap is not tight, the cosmetics will be easily polluted. If the cosmetics are used again, it will harm our skin.

3. If the pump head of the cosmetic lotion is broken, you can replace it with a new one, but the replaced pump head should match the bottle. If the replaced pump head cannot fit the cosmetic bottle closely at all, the smell of cosmetics will disperse , At the same time, it will also cause contamination of cosmetics.

In short, the cosmetic pump must be used correctly, so as to ensure its normal function, and pay attention when using it.

When choosing a lotion pump, one thing to consider is its material. The lotion pump is mainly composed of two parts, one is the shell and the other is the pump core. Lotion pumps vary in price and quality depending on the material. A good lotion pump casing can be made of engineering plastics or PET (polyester), while the pump core is made of stainless steel or die-cast aluminum, which not only have a long service life, but also meet environmental requirements. But be aware that the materials used in some cheap lotion pumps may not meet environmental protection standards, and the contents may also be recontaminated.

When purchasing a screw lotion pump , we need to pay attention to the characteristics of good material selection, practical shape, adaptability, in order to choose a cost-effective Soap lotion pump dispenser and improve product quality.

Other things about plastic Packaging

Major categories of Customized pp lotion pump

1. AS: low hardness, brittle, transparent color, and the background color is bluish, which can directly contact with cosmetics and food.

2. ABS: It belongs to engineering plastics, which is not environmentally friendly and has high hardness. It cannot be directly in contact with cosmetics and food. In acrylic cosmetic packaging materials, it is generally used for inner covers and shoulder covers, and its color is yellowish or milky white.

3. PP, PE: They are environmentally friendly materials that can be directly in contact with cosmetics and food. They are the main materials for filling organic skin care products. The natural color of the material is whitish and translucent.

4. PET: It is an environmentally friendly material that can be directly in contact with cosmetics and food. It is the main material for filling organic skin care products. The PET material is soft and its natural color is transparent.

5. PCTA, PETG: They are environmentally friendly materials that can be directly in contact with cosmetics and food. They are the main materials for filling organic skin care products. The materials are soft and transparent, and they are not commonly used for spraying and printing.

6. Acrylic: The material is hard, transparent, and the background color is whitish. In order to maintain the transparent texture, it is often sprayed inside the outer bottle, or colored during injection molding.

Types of packaging

1. Vacuum bottles: caps, shoulder sleeves, vacuum pumps, pistons.

2. Lotion bottle: consists of a cap, a shoulder sleeve, a lotion pump, and a piston. Most of them are equipped with hoses inside, and most of them are made of acrylic outside and PP inside, and the cover is made of acrylic outside and ABS inside.

3. Perfume bottle: The internal composition is glass and the external aluminum, PP bottle, glass drip irrigation, and the inner tank of the perfume bottle is mostly glass and PP.

4. Cream bottle: there are outer cover, inner cover, outer bottle and inner liner. The outside is made of acrylic, and the inside is made of PP. The cover is made of outside acrylic and inside ABS with a layer of PP gasket.

5. Blow-molded bottle: The material is mostly PET, and the caps are divided into three types: swing caps, flip caps and screw caps.

6. Blowing and injection bottles: the material is mostly PP or PE, and the caps are divided into three types: swing caps, flip caps and screw lotion pump cap .

7. Aluminum-plastic hose: the innermost one is made of PE material and the outer one is made of aluminum packaging, which is offset printed, cut and then coiled.

8. All-plastic hose: All of them are made of PE material. Pull out the hose first, then cut, offset, silk screen, and hot stamp.

Nozzle, lotion pump, hand washing pump and length measurement

1. Nozzle: bayonet and screw are all plastic, but some are covered with a layer of aluminum cover and a layer of anodized aluminum.

2. Lotion pump: It is divided into vacuum and suction tube, both of which are screw ports.

3. Hand washing pump: the caliber is too large, and they are all screw ports.

Length measurement: the length of the straw, the exposed length and the length measured under the cover.

Classification of specifications: Classification mainly depends on the inner diameter of the product or the height of the large circle.

Nozzle: 15/18/20 MM / 18/20/24 for all plastic

Lotion pump: 18/20/24 MM

Hand pump: 24/28/32(33) MM

Large ring height: 400/410/415( It’s just a simple specification code, not the actual height)

Note: The expression of specification classification is as follows: lotion pump 24/415

measurement method: there are two kinds of peeling measurement method and absolute value measurement method.

Coloring process

1. Anodized aluminum: the outer surface of aluminum is wrapped in one layer of inner plastic.

2. Electroplating (UV): Compared with the spray pattern, UV plastic lotion pump head is brighter.

3. Spraying: Compared with electroplating, the color is dull.

Spraying on the outside of the inner bottle: it is spraying on the outside of the inner bottle, there is an obvious gap between the outer bottle and the outer bottle from the outside, and the spray area is small when viewed from the side.

Spraying inside the outer bottle: It is spray-painted on the inner side of the outer bottle. It looks larger from the outside, but smaller when viewed from the vertical plane, and there is no gap with the inner bottle.

4. Brushed gold-coated silver: It is actually a film, and you can find the gaps on the bottle if you observe carefully.

5. Secondary oxidation: Secondary oxidation is carried out on the original oxide layer, so that the smooth surface is covered with dull patterns or the dull surface has smooth patterns, which are mostly used for logo production.

6. Injection molding color: Toner is added to the raw materials when the product is injected. The process is relatively cheap, and pearl powder can also be added. Adding cornstarch will make the transparent color of PET become opaque.

Printing process

1. Silk screen printing: After printing, the effect has obvious concave-convex feeling, because it is a layer of ink.

Silk screen regular bottles (cylindrical) can be printed at one time, other irregular ones are charged at one time, and colors are also charged at one time, which are divided into two types: self-drying ink and UV ink.

2. Hot stamping: a thin layer of paper is hot stamped on it, so there is no unevenness of silk screen printing.

Hot stamping is best not to be directly on the two materials of PE and PP. It needs to be heat transferred first and then hot stamped, or it can be hot stamped directly with good hot stamping paper.

3. Water transfer printing: it is an irregular printing process carried out in water, the printed lines are inconsistent, and the price is more expensive.

4. Thermal transfer printing: Thermal transfer printing is mostly used for products with large quantities and complicated printing. It belongs to attaching a layer of film on the surface, and the price is relatively expensive.

5. Offset printing: It is mostly used for aluminum-plastic hoses and lotion pump with all-plastic hoses. If the offset printing is a colored hose, Screen printing must be used when making white or sub-film.